🔹 1. To achieve uniform illumination

- The instrument panel is wide but must look evenly lit everywhere.

- If LEDs are placed directly, you’d see bright spots instead of smooth light.

- A light guide takes light from LEDs at the edge and spreads it evenly across the surface using total internal reflection (TIR) and special surface patterns.

➡️ Result: smooth, soft, and consistent lighting for numbers and symbols.

🔹 2. To reduce the number of LEDs

- Without light guides, many LEDs would be needed to cover the whole area.

- With a good light guide, only one or two LEDs can illuminate a large region.

➡️ This saves power, reduces cost, and minimizes heat buildup.

🔹 3. To control light direction and pattern

- Light guides can be optically engineered with tiny extraction features to direct light exactly where needed —

for example, to highlight speed numbers, warning icons, or the speed ring.

➡️ Designers can create sharp, stylish lighting effects with precision.

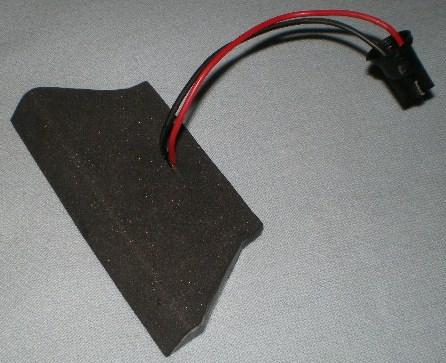

🔹 4. For durability and compact design

- Instrument clusters face heat, vibration, and long service life.

- Light guides (usually PMMA or polycarbonate) are lightweight, strong, and stable over time.

- They allow a thin, modern-looking panel design compared to bulky direct LED setups.

🔹 5. For aesthetic and optical design flexibility

- Engineers can shape the light path — bend it, curve it, or split it — to create glowing rings, accents, or ambient lighting.

➡️ This adds both functionality and premium appearance to modern dashboards.

🔸In short:

A light guide in a car dashboard makes illumination smooth, efficient, controllable, durable, and visually appealing — all with fewer LEDs and smarter optics.